In the structural design of the BA-FLS-NX5, the protection rings may not be a core component, but they play a critical role in system safety and personnel protection. Especially in harsh marine conditions, accidental collisions – such as those caused by fishing vessels or floating debris – require higher structural resilience.

At Aspiring Brothers, we employed CAE structural simulations to evaluate the double-layer protection system. We comprehensively evaluated its impact resistance capability from the overall layout to the local nodes.

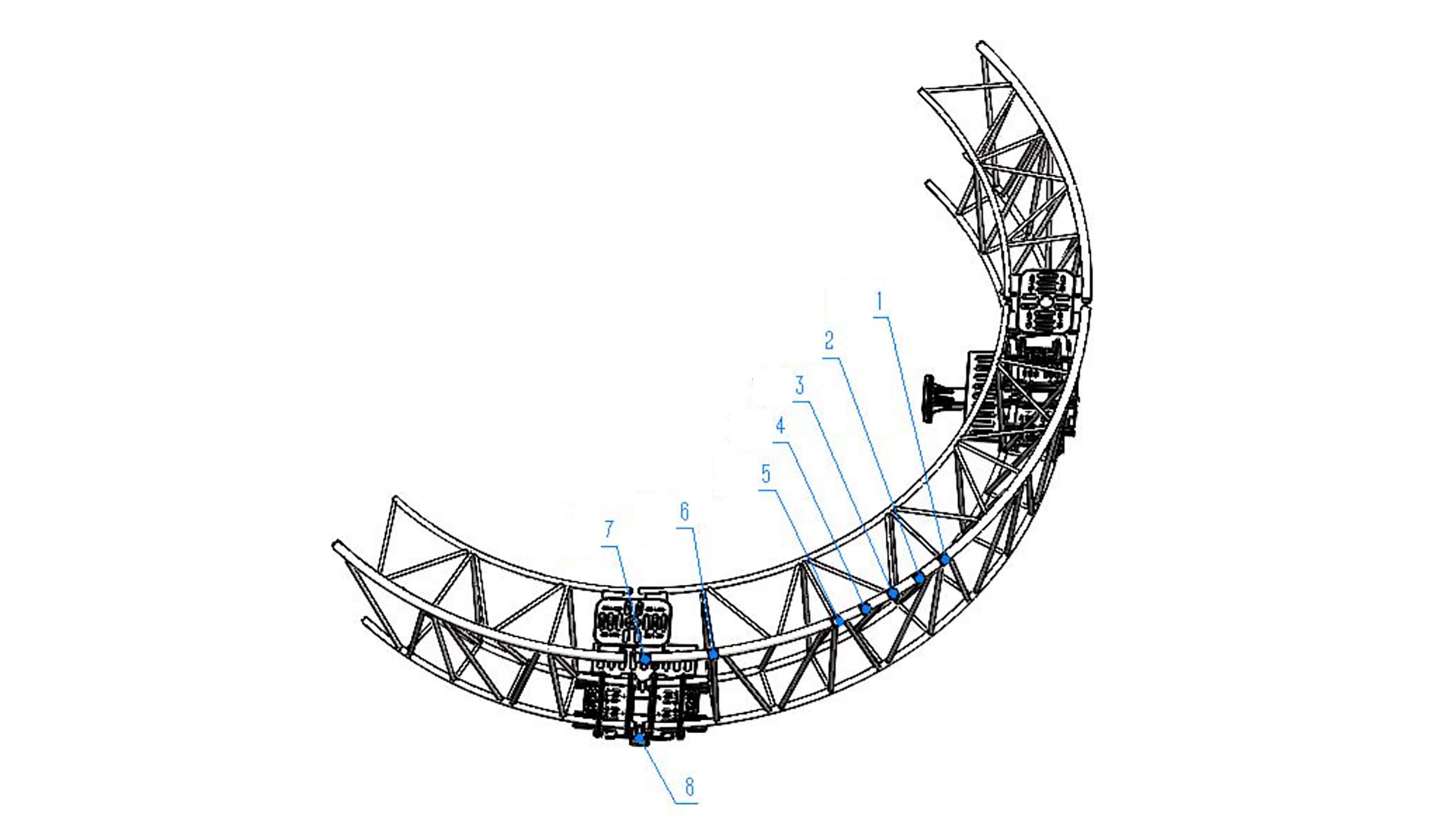

As the protection rings are symmetrically designed, we simulated the stress and strain of 8 representative nodes under load conditions, as shown in Figure 1.

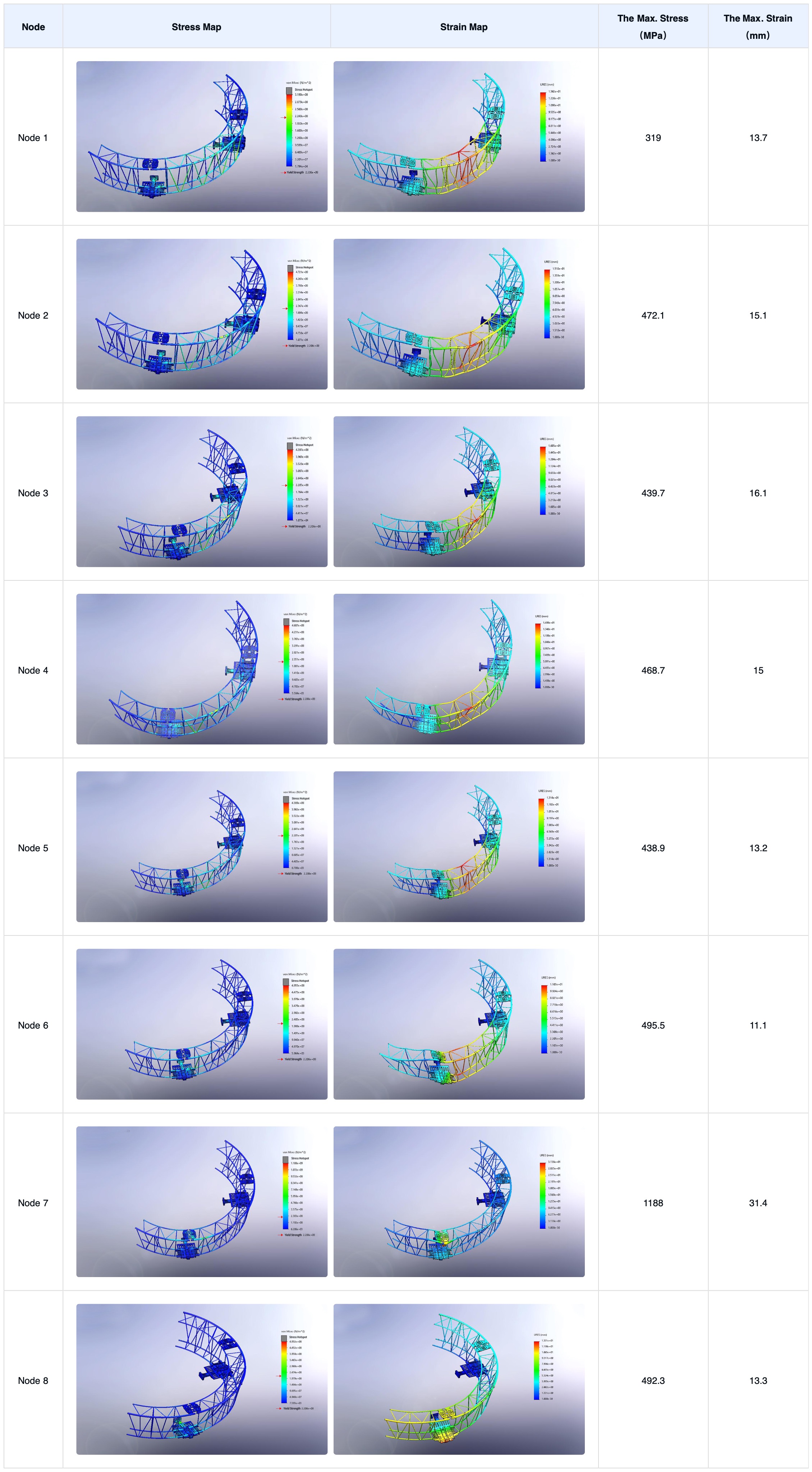

As shown in Table 1, for the key force-bearing nodes of the protection rings, a 50 kN load (equivalent to a 20-ton fishing vessel colliding at 5 knots) was applied using CAE simulation. The results indicate that Node 7 is a structural weak point. Upon failure at Node 7, the structure at Node 8 provides a second layer of protection, preventing damage to the buoy system.

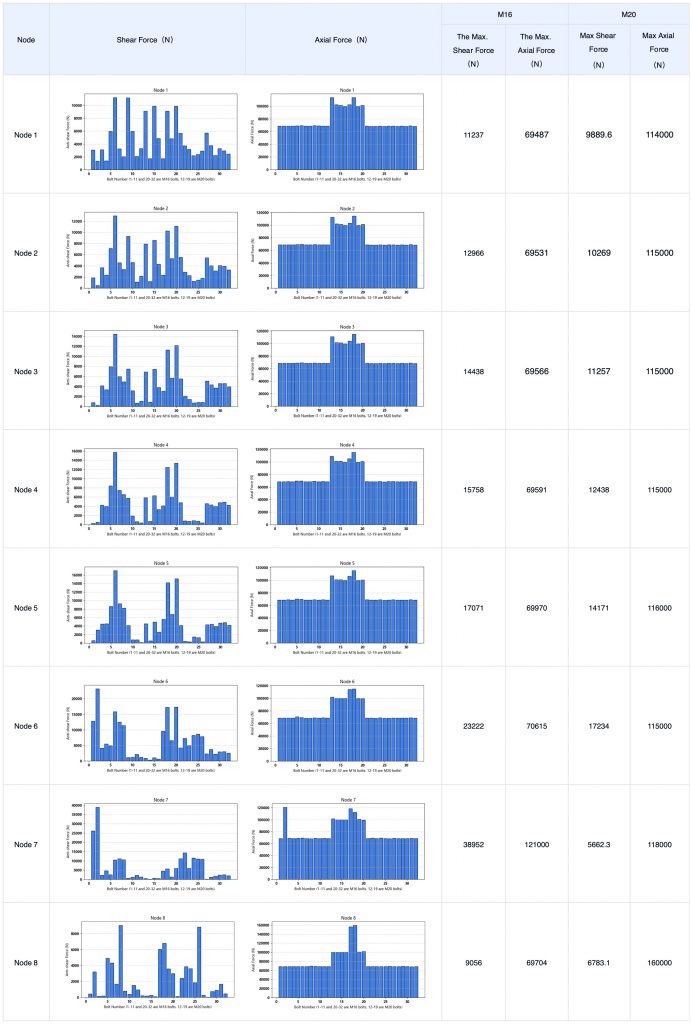

As shown in Table 2, we further simulated the shear force and axial force on M16 and M20 bolts to assess their mechanical limits. Some M16 and M20 bolts failed to meet the minimum safety factor. As a result, we upgraded critical bolts to M22 to enhance impact resistance and overall structural integrity.

Through CAE simulation, we not only identified potential failure points but also implemented effective structural optimizations. From stress evaluation to bolt selection, the entire process became traceable, quantitative, and reliable.

Simulation enables data-driven decisions, enhances product safety, and builds confidence for both engineering teams and our customers.

_左右_透明背景.png)